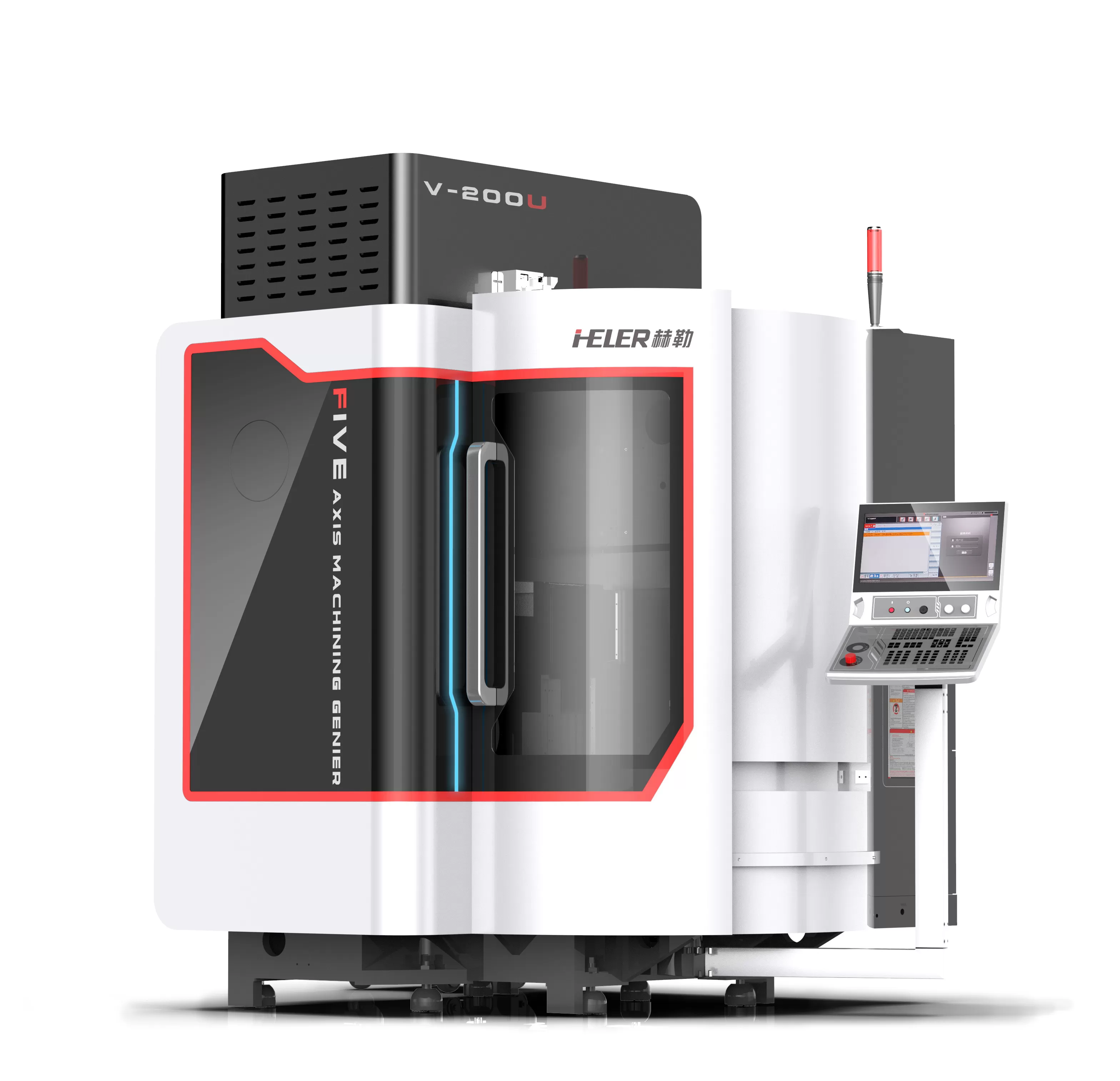

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

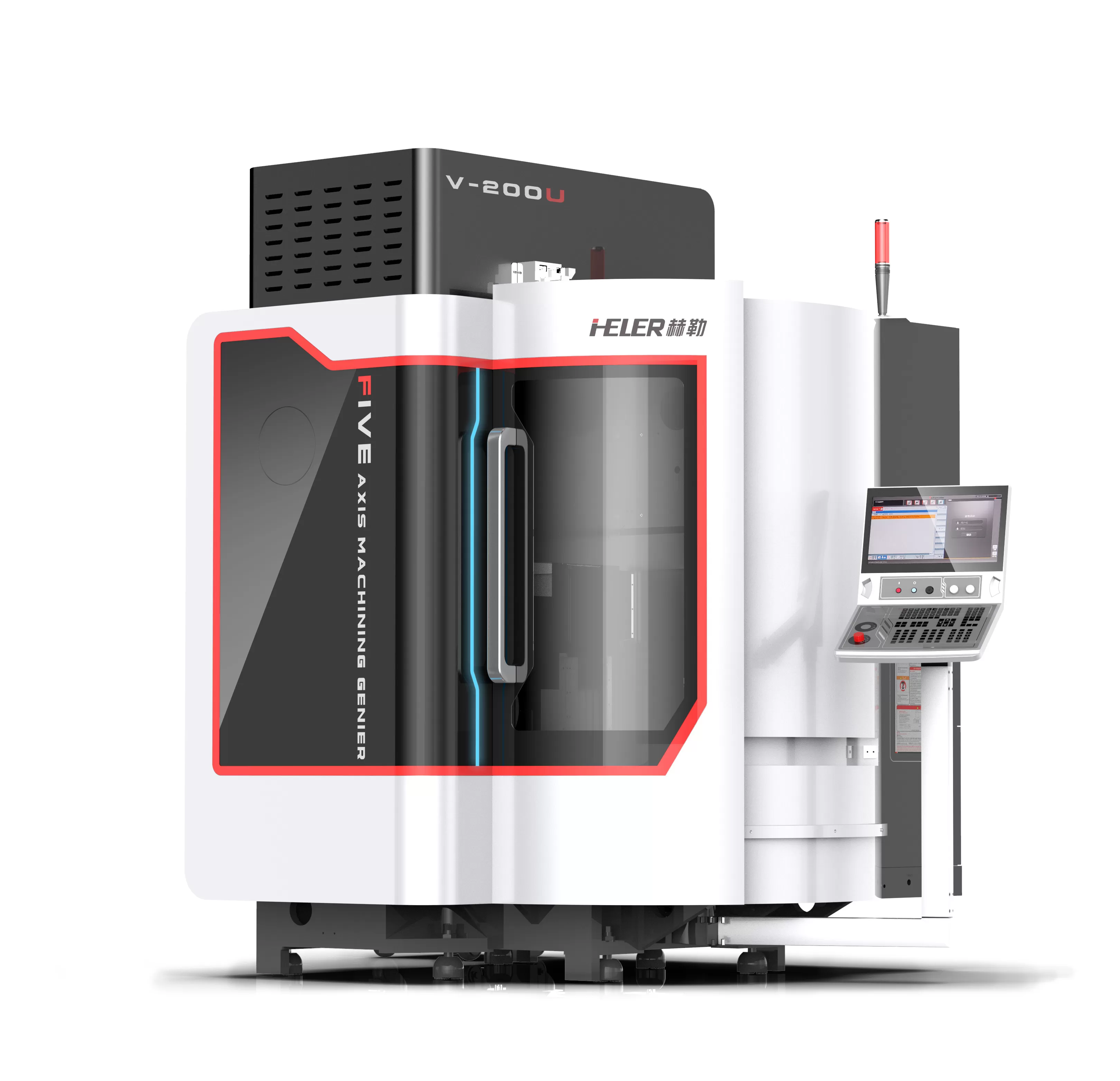

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

Vertical Machining Center

High grade gray casting machine body design through The Finite Element Method (FEA) analysis to keep light-weighted structure advantages while ensuring high machine rigidity.

All rail mounting surfaces through milling and grinding to ensure excellent precision and contact rates above 90%.

All joint surfaces of the machine body though manually scraped to ensure geometric accuracy and contact rigidity.

Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.